- This starter is used with a wound rotor induction motor. It uses an external resistance/phase in the rotor circuit so that rotor will develop a high value of torque.

- High torque is produced at low speeds, when the external resistance is at its higher value.

- At start, supply power is connected to stator through a three pole contactor and, at a same time, an external rotor resistance is added.

- The high resistance limits staring current and allows the motor to start safely against high load.

- Resistors are normally of the wire-wound type, connected through brushes and slip rings to each rotor phase. They are tapped with points brought out to fixed contactors.

- As the motor starts, the external rotor resistance is gradually cut out of circuit ; the handle or starter is turned and moves the three contacts simultaneously from one fixed contact to the next.

- The three moving contacts are interconnected to form a start point for the resistors.

- To ensure that the motor cannot be started until all rotor resistance is in circuit, an interlock is fitted which prevents the contactors from being closed until this condition is fulfilled.

2 Comments

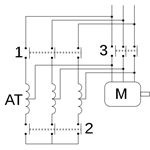

A three phase motor will give three times the power output when the stator windings are connected in delta than if connected in star, but will take 1/3 of the current from the supply when connected in star than when connected in delta. The starting torque developed in star is ½ that when starting in delta.

The 3-phase induction motors are of three types depending upon the type of rotor they employ namely

(i) Squirrel cage rotor (ii) Wound rotor or slip-ring (iii) Double squirrel cage rotor induction motors. The principle of operation is same for all types of induction motors. This is the basic principle of how induction motors work Video. There is a lot more to say about motors, as starter winding with steady capacitor, multiple pole windings, three phases motor, etc etc, but the basic theory is this one ! Did you enjoy with this video ?

Did you learn something with this video? Ok! I will ask you question about what you learnt. what induction motor consist of ?  The idea of a rotating magnetic field was developed by François Arago in 1824, and first implemented by Walter Baily.

Based on this, practical alternating current induction motors seem to have been independently invented by Nikola Tesla and Galileo Ferraris. Ferraris demonstrated a working model of his motor in 1885 and Tesla built his working model in 1887 and demonstrated it at the American Institute of Electrical Engineers in 1888(although Tesla claimed that he conceived the rotating magnetic field in 1882). In 1888, Ferraris published his research to the Royal Academy of Sciences in Turin, where he detailed the foundations of motor operation; Tesla, in the same year, was granted a United States patent for his own motor. The modern system of a three-phase transformer and induction motor with a cage was invented by Mikhail Dolivo-Dobrovolsky in 1889/1890. In this blog, my plan is to post what I’ve found useful,include some info,video,books,PPT...all about induction motor.

I hope you get benefits from our blog. Posts by: Abdullah Al-ghamdi and Yazeed Alamri. |

RSS Feed

RSS Feed