Here in this poster can include questions to get the answer or the inclusion of questions to test everyone and make educational content more fun and useful.Wait for your participation with us.

I will Start put the first question

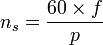

Q1/Why Does an AC Motor Need a Capacitor to Start?

You will find in this PPT all important and useful information for induction motors.

I want you to summarize some benefits from the PPT at lest one.

This technical manual for Three-Phase Induction Motors is the first publication of a series on the topic of "Motor Management".

With these published fundamentals the user will have a growing reference

work on the performance and operational data required for design and

application. The following topics will be covered:

• Starting and operating motors

• Protection of motors and drives

• Selection and operation of controls

• Communications

Electric motors can be found in almost every production process today.

Getting the most out of your application is becoming more and more

important in order to ensure cost-effective operations. "Motor Management"

from Rockwell Automation will help you:

• to optimize the use of your systems

• to reduce maintenance costs

• to increase dependability

We are pleased that our publications may help you find economical and

efficient solutions for your applications.

Content:

Design

Duty Types

Selection

Dimensioning

Copyright © 1996 by Sprecher+Schuh AG Rockwell Automation, Aarau.

All information supplied is accurate to the best of our knowledge and without legal liability.

RSS Feed

RSS Feed